RS Material Handling Inc. motor driven sortation conveyors are available in three modular designs:

- IntelliROL 30° Wheel Divert – Single Location Diverting

- IntelliROL – Pick Zone Module

- IntelliROL Urethane Belt Transfer (UBT)

IntelliROL 30° Wheel Divert – Single Location Diverting

IntelliROL (ITR) Wheel Divert allows product to be diverted off the main line to a 30° spur using pop up wheels. Product will always need to be edge aligned to the divert side prior to diverting.

Features and Benefits – IntelliROL Wheel Diverting Conveyor

- Modular design that is easy to configure

- Run on demand produces less noise, wear and energy

- Low voltage results in safety and lower cost

- Simple installation provide lower start-up costs

- Four rows of high-friction divert wheels provide reliability of the divert and maintains product orientation

- The modularity of the divert mechanism allows for easy customization and re-configuration of system

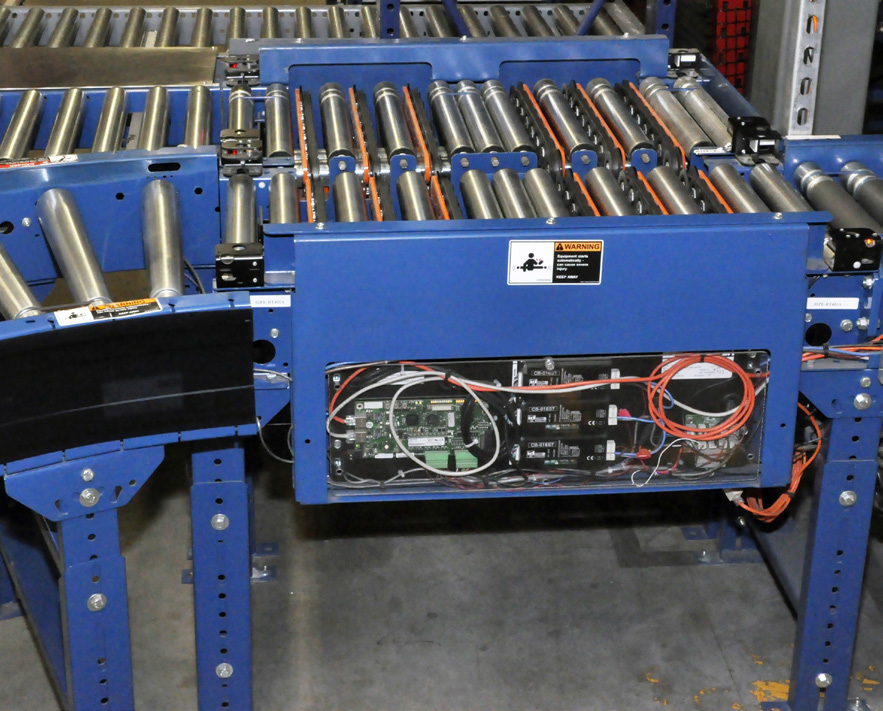

IntelliROL – Pick Zone Module (PZM)

The RS Material Handling IntelliROL Pick Zone Module (PZM) is a high-performance, cost-effective, order fulfillment solution provider. Its key is the use of a motorized roller that powers the in-feed zones, dis-charge lanes, and belts on the transfer to maximize the picking and sorting processes.

High throughput rates are achieved by transferring “on the fly” combined with a unique gravity wheel transfer. PZM is part of the IntelliROL line which is easily configured to address the needs of your warehouse. A truly modular system that can be completely customized to meet your current requirements, IntelliROL can be easily reconfigured to address your future needs when the time comes.

Features and benefits of the IntelliROL – Pick Zone Module (PZM)

- Run on demand allows for quiet operation and low energy consumption

- Few moving parts reduces maintenance cost and noise

- Transfer on-the-fly provides maximum throughput

- Use with any accumulation conveyor provide maximum flexibility

- Speed up within induction conveyor eliminates need for meter belt

- All beds are pre-wired reducing installation costs and time

- Precision bearing in all driven rollers gives quiet operation and low dB levels

- Low voltage 24VDC design is safe for close operator interaction

- Conveyors are shipped fully assembled

IntelliROL Urethane Belt Transfer (UBT)

The Urethane Belt Transfer (UBT) conveyor is designed for use with the IntelliROL product line. This provide cost-effective versatility and flexibility.

RS Material Handling has configured many variations to meet specific customer requirements. The UBT sends or receives product to/from either side of the transfer. UBT’s can be used to receive product from another conveyor or adjacent workstation or dispatch product to those positions, making them extremely popular for work-in-progress applications. UBT’s can also be used as part of an economical sortation system, achieving sort rates of up to 30 products per minute.

Features and Benefits – Urethane Belt Transfer (UBT)

- No additional motor required to power transfer, including bi-directional UBT making it energy efficient, quiet and lower operating cost

- A simple design with no high-wear points that reduces maintenance costs

- Gives a true vertical lift which keeps transfer level and minimizes product skewing

- Bi-directional unit transfers right or left on command – versatile, low cost, best value

- High belt drives offer safe operation

- Belts only run when transferring load

IntelliROL 30° Wheel Divert Images

IntelliROL – Pick Zone Module (PZM) Images

IntelliROL Urethane Belt Transfer (UBT) Images